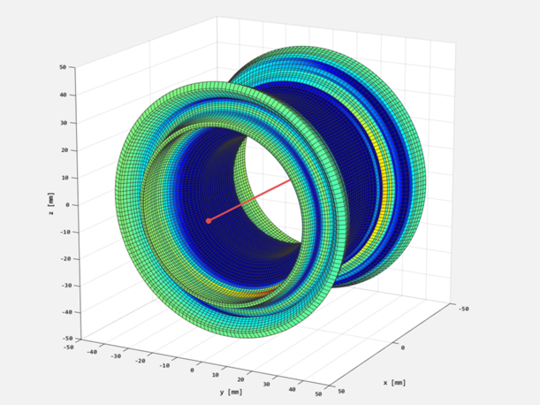

Solution approach:

In order to analyse the failure behaviour of the motor bushings, numerical simulations and service life calculations were first carried out. Real measurement data from operational measurements, which were provided by the customer for the investigation, served as a basis. Subsequently, iterative design studies were carried out to improve the component in order to find an optimal solution. Finally, the new prototype of the bushing was tested on a dynamic test field.

Results:

Through our cause analysis, an optimised design for the motor bushings could be developed for the customer. The theoretically calculated service life increase by a factor of 10 has now been confirmed by the experimental service life test, which means that the component is qualified for the planned service life of 1.8 million kilometres.