The basis of a numerical simulation that is as close to reality as possible is a sufficiently exact data basis of the material behavior. Our company strives for to get this basis as as exact as possible. Therefore, the experiments carried out in our own test laboratory are reproduced in numerical simulations and the theoretical material model is adjusted to that test data. This ensures that the material reproduces a high degree of reality even in complex loading and deformation conditions.

Material validation represents the adjustment of experimental data and simulation data. Depending on the material, it is necessary to perform certain characteristic tests in a reproducible manner.

The optimization is carried out for

- hyperelastic components

- viscoelastic components

- thermal components

in the respective material law. For elastomers there is also the possibility to consider effects like

- stress softening (Mullin's effect)

in the material. Here our company uses several strategies, for example optimization by:

- application of analytical methods

- application of numerical methods based on analytical functions (non-linear optimization)

- application of numerical methods based on simulations

The lack of material data has led our company to carry out these testson our own. This enables us to apply material models with a high mapping quality in the simulations.

Choice of material model

A decisive factor with regard to the simulation of more complex materials is the choice of the material model. Even if corresponding material data are available, it is still up to the model whether these can be mapped accordingly.

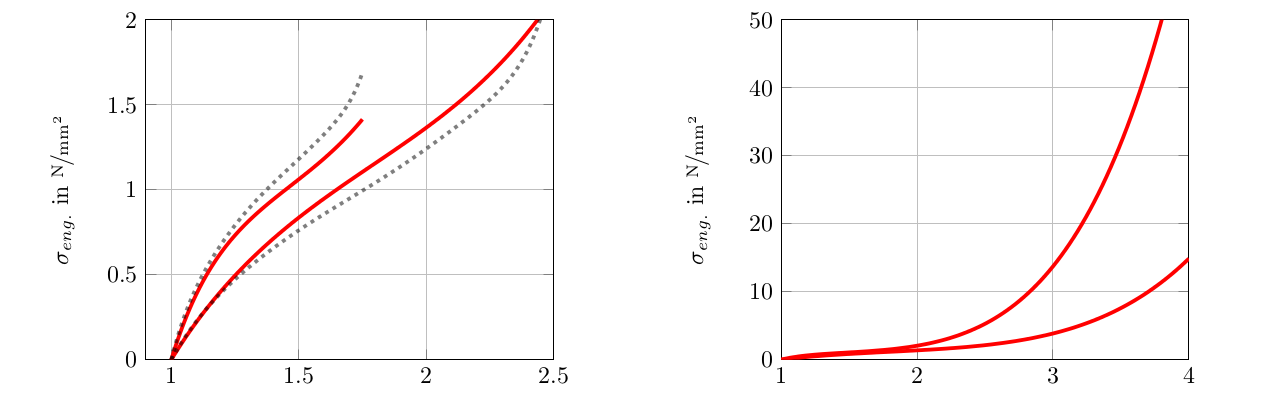

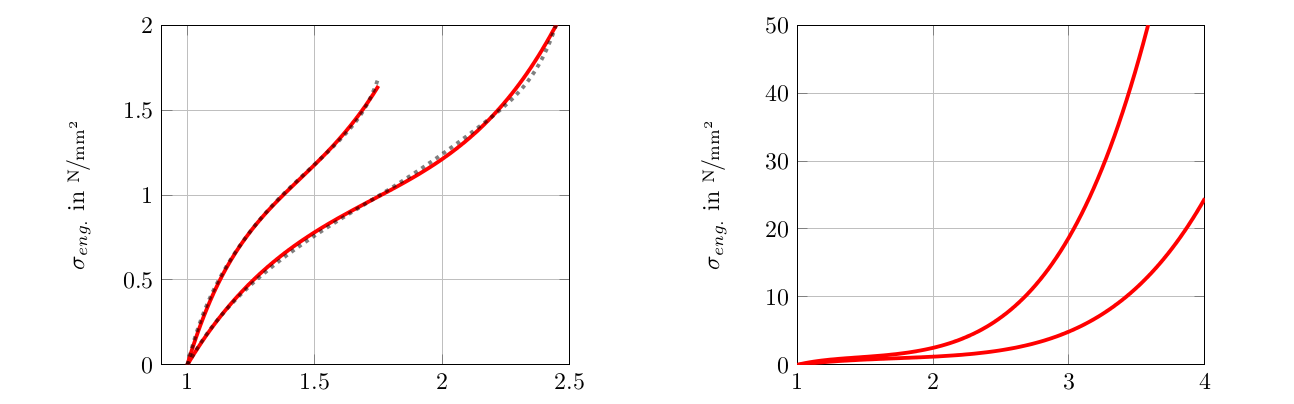

The following figures show this difference. While the simulation data (red) could be well adapted to the experimental data with a material model, this is not possible with the wrong choice of model.